DTS Sensors

under construction

under construction

under construction

INFIBRA TECHNOLOGIES can offer a range of FBG-based different sensors as well as supplies custom solution starting from single FBGs and arrays of FBGs. A short list of standard solutions is reported below, click on the picture in a selected tab to read the specifications.

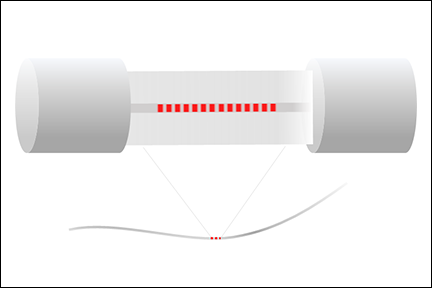

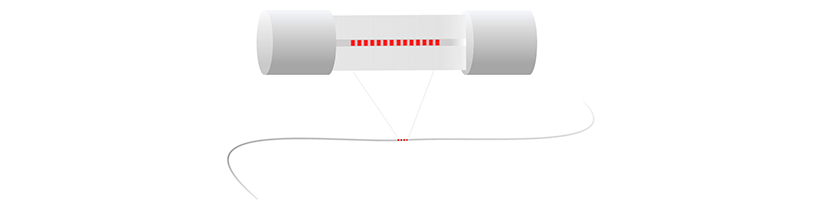

Single FBG can be used for sensing temperature and strain as well as for many physical and chemical parameters if properly packaged. Several coatings (acrylate, polyimide or metallic) and manufacturing parameters (length, bandwidth, peak reflecticvity) are available for industrial applications, even in harsh environments with ATEX and high temperatures requirements.

Single FBG can be used for sensing temperature and strain as well as for many physical and chemical parameters if properly packaged. Several coatings (acrylate, polyimide or metallic) and manufacturing parameters (length, bandwidth, peak reflecticvity) are available for industrial applications, even in harsh environments with ATEX and high temperatures requirements.

| FBG Wavelength (CWL) | 1.500 ÷ 1.600 nm (other on request) |

| FBG Wavelength tolerance (CWLT) | ± 0,5 nm (other on request) |

| FBG Bandwidth (FWHM) | 0,1 nm to 1 nm (other on request) |

| FBG Reflectivity Peak (R) | Up to 99 % (50% typical) |

| Side Lobe Suppression Ratio (SLSR) | > 15dB (other on request) |

| FBG Length (L) | 1 ÷ 12 mm (other on request) |

| Fiber Type | Standard single-mode, Bend insensitive, Pure core silica, (others on request) |

| Fiber coating | Acrylate (up to 80°C), High Temperature Acrylate (up to 150°C), Polyimide (up to 250°C, short term 400°C), Metal coating on request (up to 700°C) |

| Fiber pigtail length | 1 m both side (other on request) |

| Optical connector | FC/APC (other on request) |

| Packaging options | Tubing (e.g. polymeric, stainless steel, PEEK, PTFE), extra buffer ruggedization (other on request) |

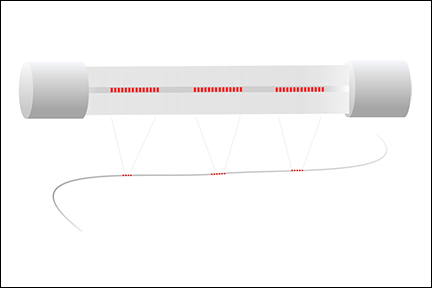

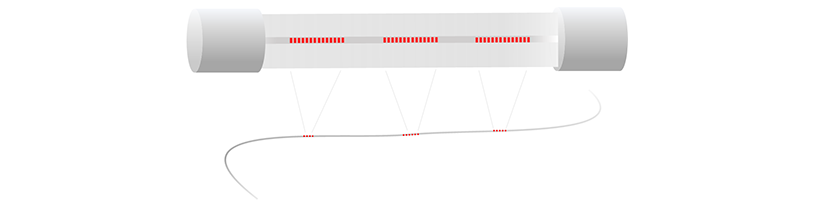

Array of FBGs can be offered in a wide range of optical specifications and material options to meet all customer requirements. It is possible to write dozens of FBG in a single optical fiber. Custom FBG spacing, several coatings and manufacturing parameters (length, bandwidth, peak reflecticvity) are available for quasi-distributed long-term sensing applications.

Array of FBGs can be offered in a wide range of optical specifications and material options to meet all customer requirements. It is possible to write dozens of FBG in a single optical fiber. Custom FBG spacing, several coatings and manufacturing parameters (length, bandwidth, peak reflecticvity) are available for quasi-distributed long-term sensing applications.

| Number of FBGs per array | Up to 50 (higher on request) |

| FBGs Spacing | >15 mm (other on request) |

| FBG Wavelength (CWL) | 1.500 ÷ 1.600 nm (other on request) |

| FBG Wavelength tolerance (CWLT) | ± 0,5 nm (other on request) |

| FBG Bandwidth (FWHM) | 0,1 nm to 1 nm (other on request) |

| FBG Reflectivity Peak (R) | Up to 99 % (50% typical) |

| Side Lobe Suppression Ratio (SLSR) | > 15dB (other on request) |

| FBG Length (L) | 1 ÷ 12 mm (other on request) |

| Fiber Type | Standard single-mode, Bend insensitive, Pure core silica, (others on request) |

| Fiber coating | Acrylate (up to 80°C), High Temperature Acrylate (up to 150°C), Polyimide (up to 250°C, short term 400°C), Metal coating on request (up to 700°C) |

| Fiber pigtail length | 1 m both side (other on request) |

| Optical connector | FC/APC (other on request) |

| Packaging options | Tubing (e.g. polymeric, stainless steel, PEEK, PTFE), extra buffer ruggedization (other on request) |

HT-Tube500 is a in-well temperature sensor for harsh environments with operating temperatures up to 500 °C (600 °C R&D). Its stainless steel rigid metallic tube (5 mm typical outer diameter) holds a cascade of FBG sensors, which enables the insertion temperature profile over the thickness of components.

HT-Tube500 is a in-well temperature sensor for harsh environments with operating temperatures up to 500 °C (600 °C R&D). Its stainless steel rigid metallic tube (5 mm typical outer diameter) holds a cascade of FBG sensors, which enables the insertion temperature profile over the thickness of components.

| Sensor Construction | Rigid Loose Tube |

| Dimension (φ x L) | Tube diameter and sensor length to suit application |

| Package material | Stainless steel AISI 304 or other options |

| Fixing method | Swagelok , Glue |

| Fiber Type | Single-mode SMF-28 9/125 μm |

| FBG Wavelength (CWL) | 1.460 ÷ 1.620 nm |

| FBG Bandwidth (FWHM) | 0,25 nm (typical) |

| FBG Peak Reflectivity (R) | > 50 % |

| Side Lobe Suppression Ratio (SLSR) | > 15dB |

| Sensors Spacing (D) | >7 mm (Customizable) |

| Sensors Number | Custom to suit application |

| Measurement Range | -50 to 500 °C (600 °C R&D) |

| Sensor Resolution | 0,1 °C (depending on FBG interrogator) |

| Sensor Accuracy | 0,5 °C (depending on FBG interrogator) |

| Cable Length and Connector | to suit application |

HT-Flex500 is a flexible temperature sensor for harsh environments with operating temperatures up to 500 °C (600 °C R&D). Its stainless steel flexible capillary tube (1.2 mm typical diameter) holds a cascade of FBG sensors, which enables both surface and embedded installations, even within extremely small wells.

HT-Flex500 is a flexible temperature sensor for harsh environments with operating temperatures up to 500 °C (600 °C R&D). Its stainless steel flexible capillary tube (1.2 mm typical diameter) holds a cascade of FBG sensors, which enables both surface and embedded installations, even within extremely small wells.

| Sensor Construction | Capillary Loose Tube |

| Dimension (φ x L) | 1.2 mm x L (Sensor Length to suit application) |

| Flexibility | Down to 300 mm diameter |

| Package material | Stainless steel AISI 304 or other options |

| Fiber Type | Single-mode SMF-28 9/125 μm |

| FBG Wavelength (CWL) | 1.460 ÷ 1.620 nm |

| FBG Bandwidth (FWHM) | 0,25 nm (typical) |

| FBG Peak Reflectivity (R) | > 50 % |

| Side Lobe Suppression Ratio (SLSR) | > 15dB |

| Sensors Spacing (D) | > 7 mm (Customizable) |

| Sensors Number | Custom to suit application |

| Measurement Range | -50 to 500 °C (600 °C R&D) |

| Sensor Resolution | 0,1 °C (depending on FBG interrogator) |

| Sensor Accuracy | 0,5 °C (depending on FBG interrogator) |

| Cable Length and Connector | to suit application |

FTT-01 is a customizable fiber-optic-based force and mechanical moment sensor designed for precision load monitoring in bolted joints and structural interfaces. Based on Fiber Bragg Grating (FBG) technology, it is engineered to function in extreme temperature environments and wide dynamic range.

FTT-01 is a customizable fiber-optic-based force and mechanical moment sensor designed for precision load monitoring in bolted joints and structural interfaces. Based on Fiber Bragg Grating (FBG) technology, it is engineered to function in extreme temperature environments and wide dynamic range.

| Form factor | Customizable (Inner hole, shape) |

| Minimum Outer Diameter | 25 mm (<25 mm R&D) |

| Minimum Thickness | 4 mm (<4 mm R&D) |

| Package material | Application customizabled (e.g. aluminum. stainless steel, titanium) |

| Operating Temperature | -80 °C to +250 °C |

| IP Grade | up to IP68 |

| Measurement Capacities | > 30 kN |

| Sensor Technology | Multiple Fiber Bragg Gratings (FBGs) |

| Resolution | Up to 0.05% of full scale (application dependent) |

| Sampling Rate | Depending on used FBG interrogator |

| FBG Central Wavelength | Within the range 1460 ÷ 1620 nm |

| FBG Bandwidth | 1 nm (typical) |

| Temperature Compensation | Reference Temperature FBGs (optional) |

INFIBRA TECHNOLOGIES can offer a range of FBG interrogators based on the different technologies provided by its international partners. Listed below you can find the proprietary instruments only, click on the picture in a selected tab to read the specifications.

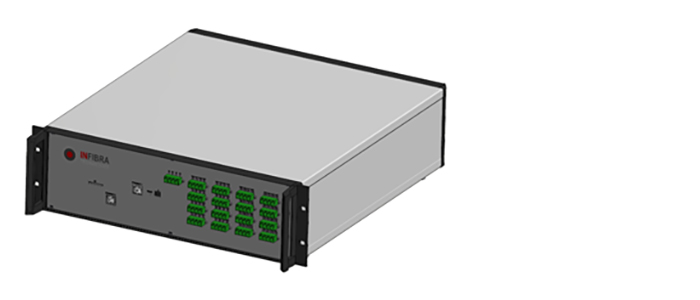

FBG.HUB UNIT is an active multiplexer which can be used in combination with FBG interrogators for the acquisition, log and communication of FBG-based sensors. Each of 4 input channels can be connected to a channel of a compatible FBG interrogator in order to expand the acquisition channel from 1 to 16. This capability allows the acquisition of 4 x 16 = 64 switched channels.

FBG.HUB UNIT is an active multiplexer which can be used in combination with FBG interrogators for the acquisition, log and communication of FBG-based sensors. Each of 4 input channels can be connected to a channel of a compatible FBG interrogator in order to expand the acquisition channel from 1 to 16. This capability allows the acquisition of 4 x 16 = 64 switched channels.

| Wavelength Range | 300 nm (1300-1600 nm) |

| Number of Input Channels | 4 |

| Number of Output Channels | 64 |

| Insertion Loss | <1.7 dB (Typical 0.7 dB) |

| Number of sensors | Depending on FBG interrogator |

| Polarization dependent loss | < 0.15 dB |

| Repeatability | < 0.01 dB |

| Minimum switching time | < 10 ms (typical 5 ms) |

| Durability | MEMS technology - no wear out |

| Communication | TCP/IP Modbus |

| Onboard Logging | External SD for logging |

| Certifications | CE |

| Dimensions | 19" standard RACK, 3U height, 84HP depth |

| Weight | 3 kg |

| Operating Temperature | -10 to 50 °C (10-90% RH non condensating) |

| Storage temperature | -20 to 85 °C |

| Comms Interface | Ethernet |

| Optical Connector | LC/APC |

| Power supply | 19 - 36 Vdc (typical 24 Vdc) |

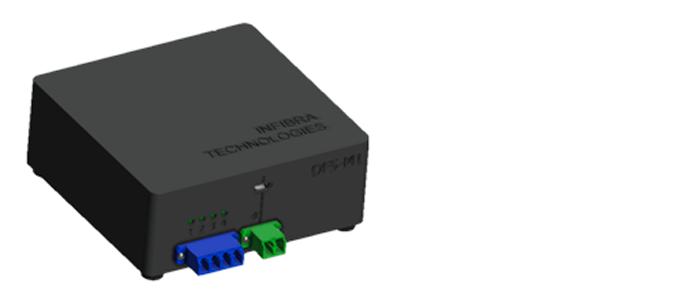

OFS-M1 is an active opto-electronic device which can be used in combination with FBG interrogators in order to direct the optical signal from an input port to one of its output ports. In particular, it acts as a dynamic light path switch, with portability capability, controllable through a PC connected to the device via USB port.

OFS-M1 is an active opto-electronic device which can be used in combination with FBG interrogators in order to direct the optical signal from an input port to one of its output ports. In particular, it acts as a dynamic light path switch, with portability capability, controllable through a PC connected to the device via USB port.

| Wavelength Range | 420 nm (1250-1670 nm) |

| Number of Input Channels | 1 |

| Number of Output Channels | 4 |

| Insertion Loss | <1 dB (Typical 0.5 dB) |

| Number of sensors | Depending on FBG interrogator |

| Repeatability | <0.1 dB |

| Minimum switching time | <10 ms (Typical 5 ms) |

| Communication | USB – Driver Labview included |

| Certifications | CE |

| Dimensions | 125 mm x 52.6 mm x 136 mm |

| Weight | 100 g |

| Operating Temperature | -10 to 70 °C (10-90% RH non condensating) |

| Storage temperature | -20 to 85 °C |

| Comms Interface | USB |

| Optical Connector | LC/APC |

| Power supply | 5 Vdc (micro-USB) |

We strongly believe in cooperation with our partners and that one of the keys to the successful application of fiber optic sensors lies in their embedding capability. For that purpose, we offer several integration services in materials, structures and assets in general.

We strongly believe in cooperation with our partners and that one of the keys to the successful application of fiber optic sensors lies in their embedding capability. For that purpose, we offer several integration services in materials, structures and assets in general.

Our laboratories are comprehensive of equiments and softwares for:

- FEM/CFD Analysis and Simulation

- Mechanical Design and CAD/CAM Modeling

- Data Analysis and Modeling

- Fiber and Cable Processing

- Opto-Electronic Assembly and Test

- Inspection and Quality Control

- Thermo-Mechanical Calibration

- Embedded Systems and Automation

INFIBRA TECHNOLOGIES Srl is engaged in designing and manufacturing of next-generation fiber optic sensors systems, while also offering engineering services. Energy, Oil & Gas, Transportation and Civil Engineering are our target markets, with solutions even suitable for harsh environments. Monitoring of temperature, vibration, deformation, or other chemical-physical parameters through a single optical fiber are our typical applications and FBGs, Raman, Brillouin and Rayleigh are our technologies.

Via Emilia 323/A, Pisa, 56121 - VAT 02134410501

+39 050 7917951

info@infibratechnologies.com